The perfect storm: Why everything is in place for 2025 to be the year of GxP AI

For years, artificial intelligence has been a topic of discussion in pharmaceutical manufacturing, but adoption has been slow and limited to a few forward-thinking pioneers. That’s already changing. A unique confluence of factors, from regulatory readiness to competitive pressure, is creating the perfect storm for AI adoption in GxP manufacturing. 2025 is poised to be the tipping point when AI moves from being a competitive edge for early adopters to an industry-wide must-have, reshaping pharmaceutical production as we know it.

A shift in mindset

Until recently, many in the industry viewed AI as a futuristic concept—promising, but decades away for such a risk-averse sector. That mindset has now changed. The explosion of generative AI, particularly large language models (LLMs), has propelled artificial intelligence into the mainstream, bringing it to the forefront of boardroom discussions. LLMs’ success in areas like drug discovery has helped shift perceptions, making AI no longer a novelty but a necessity.

However, it is worth noting that in the area of pharmaceutical manufacturing LLMs take a backseat to machine learning (ML). In GMP environments, ML has already proven its ability to reduce lead time, cut costs, and increase yield, leading to a new level of confidence in AI’s potential. Unlike LLMs, which are designed for language-based tasks, machine learning excels at making sense of complex manufacturing data, driving efficiency, and ensuring quality at scale. As AI adoption accelerates across pharma, it’s ML—not LLMs—that is poised to transform manufacturing.

The technology is ready

Another key factor driving AI adoption in 2025 is that the technology has matured to a level where it can be effectively and reliably deployed in GMP environments. AI-driven predictive analytics, real-time process control, and machine learning models are no longer theoretical—they are already delivering undeniable results, improving yield, reducing waste, and enhancing compliance in the facilities that have embraced them.

Cloud-based analytics platforms now allow AI solutions to be rapidly deployed, eliminating the barriers of high infrastructure costs and lengthy implementation timelines. AI-powered tools are now scalable, adaptable, and designed to meet the specific needs of pharmaceutical manufacturers, making it easier than ever to integrate them into existing systems without disrupting operations.

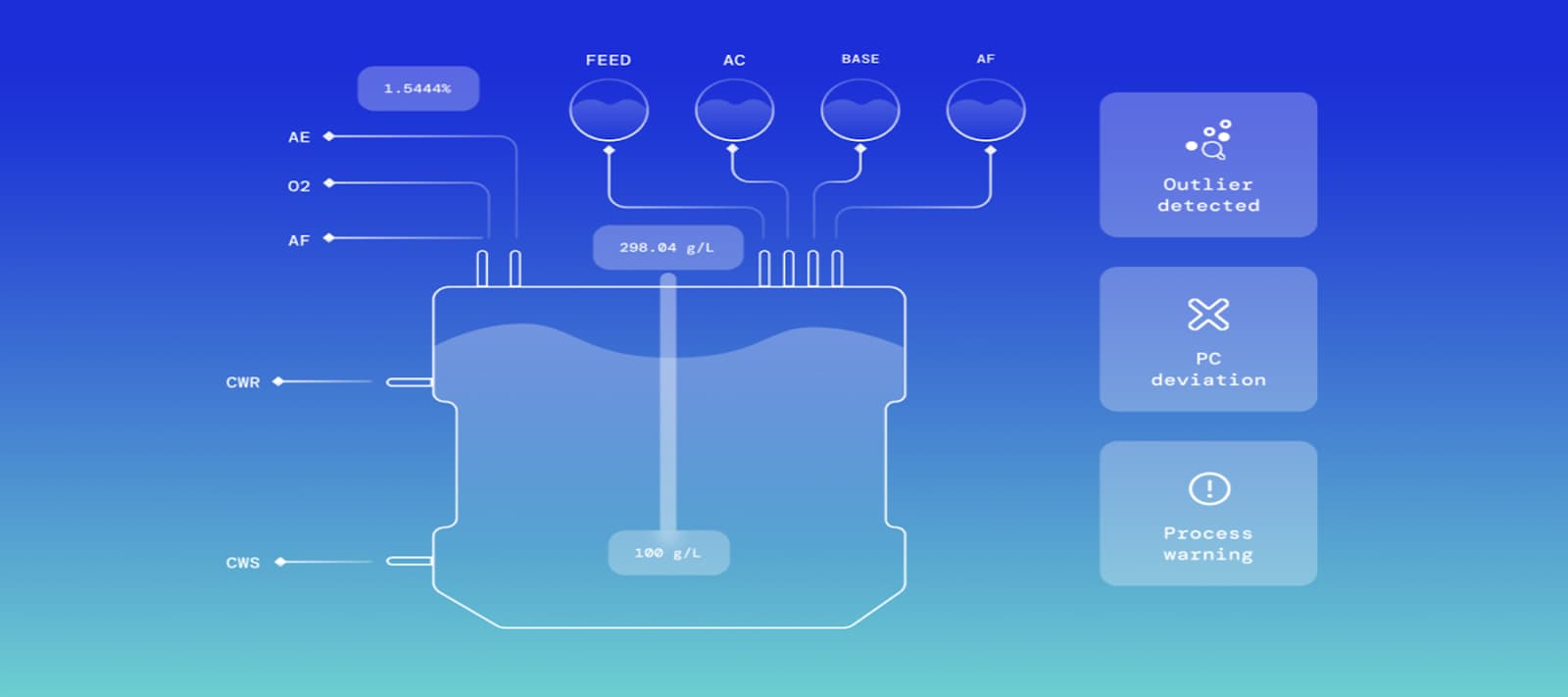

On the other hand, while many Big Pharma companies have already developed their own AI models and are benefiting from them in controlled environments, they face a significant challenge when it comes to operationalizing them at scale. How do you industrialize these models? How do you validate them in a GxP-compliant way? This is where Aizon Predict stands out, providing a purpose-built solution that ensures AI models are seamlessly integrated, validated, and effectively deployed in GMP manufacturing environments.

Regulatory frameworks have caught up

Historically, a barrier to the adoption of innovative Technology in the pharmaceutical industry has been regulatory uncertainty. And so it has been with AI: companies have hesitated to invest in AI-powered solutions without clear guidance on compliance. However, in a rare turn of events, regulators have moved ahead of industry adoption, laying the groundwork for AI-driven manufacturing.

The FDA’s “Artificial Intelligence and Machine Learning (AI/ML) – Enabled Medical Devices” guidance is a clear indicator of this shift. Other regulatory agencies around the world are following suit, creating frameworks that not only permit AI in pharmaceutical manufacturing but actively encourage it. This regulatory clarity removes a significant roadblock, allowing companies to invest in AI solutions with confidence that compliance will not be a barrier to adoption.

Manufacturing data is more abundant than ever

One of AI’s greatest strengths is its ability to make sense of vast amounts of data. In recent years, pharmaceutical manufacturers have been generating more data than ever before, thanks to increased digitalization, automation, and connected systems. However, much of this data remains underutilized due to the limitations of traditional data analysis tools.

The good news is, current AI-powered solutions make it possible to unlock the full potential of this data by integrating, contextualizing, and analyzing it in real time. The crucial leap of moving from paper to digital batch records, for instance, can now be taken in a matter of weeks thanks to tools like Aizon Execute. The next step, in which data from multiple sources is digitized and contextualized, can be achieved with an intelligent lakehouse like Aizon Unify. This paves the way for advanced AI models to uncover hidden patterns, optimize processes, and provide predictive insights that prevent failures before they occur. This ability to extract meaningful intelligence from data is currently a competitive advantage. Soon, it will become an operational necessity. As the volume of data continues to grow, the need to make the most of it will become imperative, making AI’s role in pharmaceutical manufacturing even more indispensable.

The pressure of competition

Another driving force behind AI adoption in 2025 is the growing competitive pressure within the pharmaceutical manufacturing industry. Compounding this pressure, for many, will be a justified sense of FOMO: an awareness that companies that fail to harness AI risk falling behind in terms of efficiency, quality control, and cost-effectiveness.

This pressure is particularly pronounced in the CDMO space, where contract manufacturers operate on thin margins and are constantly seeking ways to optimize production. AI-driven process improvements, predictive maintenance, and real-time quality monitoring provide CDMOs with a clear advantage, allowing them to offer better service at lower costs. As more CDMOs integrate AI into their operations, pharmaceutical companies will face increasing pressure to do the same to remain competitive.

Approaching the tipping point for GxP AI

With the convergence of these factors—shifting perceptions, technological readiness, regulatory alignment, data availability, and competitive pressure—2025 is set to be the year AI moves from early adoption to mainstream implementation in GxP manufacturing. The groundwork has been laid, the industry is ready, and companies that act now will be best positioned for success.

Solutions tailored for GMP environments, such as Aizon Execute for intelligent batch records and Aizon Unify for seamless data integration, ensure that manufacturing data is available, structured, and contextualized, enabling the application of AI models with Aizon Predict for advanced manufacturing analytics. These technologies are already helping manufacturers accelerate digital transformation, shift into data-driven manufacturing, and optimize their processes. By leveraging AI-powered analytics, made possible by robust data management tools, pharmaceutical manufacturers can confidently transition toward a smarter, more efficient, and more compliant future.

AI solutions that make it possible to tailored for GMP environments, such as Aizon Execute for Intelligent Batch Records, Aizon Unify for seamless data integration, and Aizon Predict for advanced manufacturing analytics, are already helping manufacturers accelerate their digital transformation, shift into data-driven manufacturing, and optimize their processes. By leveraging AI-powered platforms to enhance operational visibility, improve product quality, and reduce deviations, pharmaceutical manufacturers can confidently transition toward a smarter, more efficient, and more compliant future.

To learn more about how AI can revolutionize pharmaceutical manufacturing, watch our webinar, ‘The Hidden Gem of GxP AI‘.